Fiber Optic Solutions

We provide conventional cabling solutions that compliment the deployment of optical solutions deeper into the network delivering a future-proof infrastructure. We have highly skilled and trained fiber optic technicians using state-of-the-art tools and test equipment to ensure that your fiber optic cabling is installed proficiently with optimal end faces on every connector. Our highly trained and skilled team can install and test any type of field connector or fusion splice any factory pigtail desired. We stay on top of new fiber optic products and practices so we can continuously meet the growing demands for optical fiber installations.

We provide conventional cabling solutions that compliment the deployment of optical solutions deeper into the network delivering a future-proof infrastructure. We have highly skilled and trained fiber optic technicians using state-of-the-art tools and test equipment to ensure that your fiber optic cabling is installed proficiently with optimal end faces on every connector. Our highly trained and skilled team can install and test any type of field connector or fusion splice any factory pigtail desired. We stay on top of new fiber optic products and practices so we can continuously meet the growing demands for optical fiber installations.

Single Mode Fiber is used to connect long distance runs usually to connect buildings. This mode of Fiber is bit expensive to run but is an ideal choice for huge data transfer over long distances.

Single Mode Fiber is used to connect long distance runs usually to connect buildings. This mode of Fiber is bit expensive to run but is an ideal choice for huge data transfer over long distances.- Multi Mode Fiber is an ideal replacement for copper or Ethernet Cabling. These fiber Cables runs are ideally used where distance of copper cable exceeds 295 feet. Multimode Fiber can provide 10 Gigabit Ethernet (10Gbit/s) at distances of up to 300 meters.

Cable Types

Tight buffer cables (Simplex, Zipcord, Distribution and Breakout) are used where cable flexibility and ease of termination are important, more so than ruggedness and pulling strength which characterize loose tube and ribbon types of cable. Generally, tight buffer cables are used indoors and loose tube/ribbon cables outdoors.

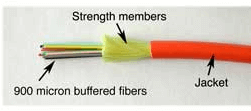

Simplex and Zip Cord

These types are used mostly for patch cord and backplane applications, but zipcord can also be used for desktop connections. Simplex cables are one fiber, tight-buffered (coated with a 900 micron buffer over the primary buffer coating) with Kevlar (aramid fiber) strength members and jacketed for indoor use. The jacket is usually 3mm (1/8 in.) diameter. Zipcord is simply two of these joined with a thin web.

These types are used mostly for patch cord and backplane applications, but zipcord can also be used for desktop connections. Simplex cables are one fiber, tight-buffered (coated with a 900 micron buffer over the primary buffer coating) with Kevlar (aramid fiber) strength members and jacketed for indoor use. The jacket is usually 3mm (1/8 in.) diameter. Zipcord is simply two of these joined with a thin web.

Distribution Cables

Distribution cable is the most popular indoor cable, as it is small in size and light in weight. They contain several tight-buffered fibers bundled under the same jacket with Kevlar strength members and sometimes fiberglass rod reinforcement to stiffen the cable and prevent kinking. These cables are small in size, and used for short, dry conduit runs, riser and plenum applications. The fibers are double buffered and can be directly terminated, but because their fibers are not individually reinforced, these cables need to be broken out with a "breakout box" or terminated inside a patch panel or junction box to protect individual fibers.

Distribution cable is the most popular indoor cable, as it is small in size and light in weight. They contain several tight-buffered fibers bundled under the same jacket with Kevlar strength members and sometimes fiberglass rod reinforcement to stiffen the cable and prevent kinking. These cables are small in size, and used for short, dry conduit runs, riser and plenum applications. The fibers are double buffered and can be directly terminated, but because their fibers are not individually reinforced, these cables need to be broken out with a "breakout box" or terminated inside a patch panel or junction box to protect individual fibers.

Breakout Cables

Breakout cable is a favorite where rugged cables are desirable or direct terminati on without junctionboxes, patch panels or other hardware is needed. They are made of several simplex cables bundled together insdie a common jacket. This is a strong, rugged design, but is larger and more expensive than the distribution cables. It is suitable for conduit runs, riser and plenum applications. It's perfect for industrial applications where ruggedness is needed. Because each fiber is individually reinforced, this design allows for quick termination to connectors and does not require patch panels or boxes. Breakout cable can be more economic where fiber count isn't too large and distances too long, because is requires so much less labor to terminate.

Breakout cable is a favorite where rugged cables are desirable or direct terminati on without junctionboxes, patch panels or other hardware is needed. They are made of several simplex cables bundled together insdie a common jacket. This is a strong, rugged design, but is larger and more expensive than the distribution cables. It is suitable for conduit runs, riser and plenum applications. It's perfect for industrial applications where ruggedness is needed. Because each fiber is individually reinforced, this design allows for quick termination to connectors and does not require patch panels or boxes. Breakout cable can be more economic where fiber count isn't too large and distances too long, because is requires so much less labor to terminate.

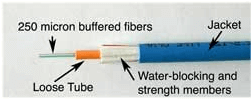

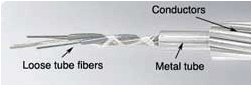

Loose Tube Cables

Loose tube cables are the most widely used cables for outside plant trunks because it offers the best protection for the fibers under high pulling tensions and can be easily protected from moisture with water-blocking gel or tapes.These cables are composed of several fibers together inside a small plastic tube, which are in turn wound around a central strength member, surrounded by aramid strength members and jacketed, providing a small, high fiber count cable. This type of cable is ideal for outside plant trunking applications, as it can be made with the loose tubes filled with gel or water absorbent powder to prevent harm to the fibers from water. It can be used in conduits, strung overhead or buried directly into the ground. Some outdoor cables may have double jackets with a metallic armor between them to protect from chewing by rodents or kevlar for strength to allow pulling by the jackets. Since the fibers have only a thin buffer coating, they must be carefully handled and protected to prevent damage. Loose tube cables with singlemode fibers are generally terminated by spicing pigtails onto the fibers and protecting them in a splice closure. Multimode loose tube cables can be terminated directly by installing a breakout kit, also called a furcation or fan-out kit, which sleeves each fiber for protection.

Loose tube cables are the most widely used cables for outside plant trunks because it offers the best protection for the fibers under high pulling tensions and can be easily protected from moisture with water-blocking gel or tapes.These cables are composed of several fibers together inside a small plastic tube, which are in turn wound around a central strength member, surrounded by aramid strength members and jacketed, providing a small, high fiber count cable. This type of cable is ideal for outside plant trunking applications, as it can be made with the loose tubes filled with gel or water absorbent powder to prevent harm to the fibers from water. It can be used in conduits, strung overhead or buried directly into the ground. Some outdoor cables may have double jackets with a metallic armor between them to protect from chewing by rodents or kevlar for strength to allow pulling by the jackets. Since the fibers have only a thin buffer coating, they must be carefully handled and protected to prevent damage. Loose tube cables with singlemode fibers are generally terminated by spicing pigtails onto the fibers and protecting them in a splice closure. Multimode loose tube cables can be terminated directly by installing a breakout kit, also called a furcation or fan-out kit, which sleeves each fiber for protection.

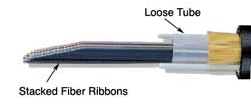

Ribbon Cable

Ribbon cable is preferred where high fiber counts and small diameter cables are needed.This cable has the most fibers in the smallest cable, since all the fibers are laid out in rows in ribbons, typically of 12 fibers, and the ribbons are laid on top of each other. Not only is this the smallest cable for the most number of fibers, it's usually the lowest cost. Typically 144 fibers only has a cross section of about 1/4 inch or 6 mm and the jacket is only 13 mm or 1/2 inch diameter! Some cable designs use a "slotted core" with up to 6 of these 144 fiber ribbon assemblies for 864 fibers in one cable! Since it's outside plant cable, it's gel-filled for water blocking or dry water-blocked. Another advantage of ribbon cable is Mass Fusion Splicers can join a ribbon (12 fibers) at once, making installation fast and easy. Ribbon pigtails are spliced onto the cable for quick termination.

Ribbon cable is preferred where high fiber counts and small diameter cables are needed.This cable has the most fibers in the smallest cable, since all the fibers are laid out in rows in ribbons, typically of 12 fibers, and the ribbons are laid on top of each other. Not only is this the smallest cable for the most number of fibers, it's usually the lowest cost. Typically 144 fibers only has a cross section of about 1/4 inch or 6 mm and the jacket is only 13 mm or 1/2 inch diameter! Some cable designs use a "slotted core" with up to 6 of these 144 fiber ribbon assemblies for 864 fibers in one cable! Since it's outside plant cable, it's gel-filled for water blocking or dry water-blocked. Another advantage of ribbon cable is Mass Fusion Splicers can join a ribbon (12 fibers) at once, making installation fast and easy. Ribbon pigtails are spliced onto the cable for quick termination.

Armored Cable

Armored cable is used in direct buried outside plant applications where a rugged cable is needed and/or rodent resistance. Armored cable withstands crush loads well, needed for direct burial applications. Cable installed by direct burial in areas where rodents are a problem usually have metal armoring between two jackets to prevent rodent penetration. Another application for armored cable is in data centers, where cables are installed underfloor and one worries about the fiber cable being crushed. Armored cable is conductive, so it must be grounded properly.

Armored cable is used in direct buried outside plant applications where a rugged cable is needed and/or rodent resistance. Armored cable withstands crush loads well, needed for direct burial applications. Cable installed by direct burial in areas where rodents are a problem usually have metal armoring between two jackets to prevent rodent penetration. Another application for armored cable is in data centers, where cables are installed underfloor and one worries about the fiber cable being crushed. Armored cable is conductive, so it must be grounded properly.

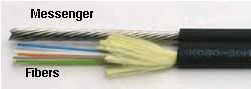

Aerial Cable

Aerial cables are for outside installation on poles. They can be lashed to a messenger or another cable (common in CATV) or have metal or aramid strength members to make them self supporting. The cable shown has a steel messenger for support. It must be grounded properly.

Aerial cables are for outside installation on poles. They can be lashed to a messenger or another cable (common in CATV) or have metal or aramid strength members to make them self supporting. The cable shown has a steel messenger for support. It must be grounded properly.

A widely used aerial cable is optical power ground wire (OPGW) which is a high voltage distribution cable with fiber in the center. The fiber is not affected by the electrical fields and the utility installing it gets fibers for grid management and communications. This cable is usually installed on the top of high voltage towers but brought to ground level for splicing or termination.

A widely used aerial cable is optical power ground wire (OPGW) which is a high voltage distribution cable with fiber in the center. The fiber is not affected by the electrical fields and the utility installing it gets fibers for grid management and communications. This cable is usually installed on the top of high voltage towers but brought to ground level for splicing or termination.

Hybrid and Composite Cables

These two types of cables are often confused, but almost everybody and the NEC defines them as:

- Hybrid cables: Cables that contain two types of fibers, usually multimode and singlemode. These cables are often used in campus and premises backbones where the singlemode fibers may be used in the future.

- Composite cables: Cables that contain both fibers and electrical conductors. Underwater tethered vehicles use cables like this, as do some cables used for remoting wireless antennas or CCTV cameras. These cables must be properly grounded and bonded for safety.

Milestone has staff that is trained and certified by the Fiber Optic Association as Certified Fiber Optic Technicians. We can install, terminate, test, certify and troubleshoot all of your fiber optic cabling needs with the latest in tools, test equipment and technology available today in this ever changing market.